BASES, CAKE STANDS, NUMERBERS

Modecor

2004

|

Concreativity means to realize projects with experience and efficiency, creativity and a 100% Italian quality. For over 50 years, specialized in the industrial processing of metals and plastics, Terenzi Srl it has being a center of expertise and it offers integrated products and services. |

|

It designs, manufactures and assembles components or finished, technical or design products through molds or laser cutting, punching (also combined cycle), bending and typical processes of light precision carpentry. The molds for blanking, drawing and injection of thermoplastics are made by our internal tooling department. |

|

The careful evaluation of all aspects of the orders, the constant updating of skills and the renewal of applied technologies, the careful selection of the raw materials make the processes innovative, dynamic and optimized, reaching high quality standards, also attentive to environmental sustainability and to the future of the planet. |

1967 |

||

1970 |

||

1974 |

||

1975 |

||

1980 |

||

1982 |

||

1991 |

||

1995 |

||

1996 |

||

1997 |

||

1998 |

||

2004 |

||

2006 |

||

2007 |

||

2009 |

||

2010 |

||

2013 |

||

2014 |

||

2015 |

||

2016 |

||

2017 |

||

2018 |

||

2019 |

||

2020 |

||

2021 |

||

2022 |

||

2023 |

||

2024 |

TERENZI of Angelo Terenzi is born as a punch company in 1967 in Tregarezzo (Segrate). During its first years of activities, it produces various accessories, such as buckles and buttons for big names: Levì's, Fiorucci, Wrangler and Happening.

CloseFrom initial Shearing Company TERENZI evolves. The Department of Electroplating and the units of Design and Tooling for the project and manufacture of molds are added. New orders are acquired in various sectors and it develops a multi-faceted experience.

CloseThanks to the three new Departments of Design, Tooling and Electroplating along with the original Shearing, skills are developed and directed to technology areas. Other collaborations start consequently with companies such as Igv and Sirai Elettromeccanica.

CloseELCO, specialized in assembly, is added to complete the job of producing of TERENZI and to acquire a significant task of electromechanical assembly for the Co. Fantini and Cosmi.

CloseTERENZI becomes a Srl (limited company) and with ELCO acquires a new office in San Giuliano Milanese. From the USA one of the first wire EDM with numerical control is imported. From this point on, the company covers and gradually integrates new services and processes, expanding and renewing its machines in parallel.

CloseThe implement and development of services continues, TERENZI Srl is increasingly a center of expertise: we offer heat treatments, coating or galvanizing.

CloseThe merger between the Punching Dpt. and the Tooling Dpt. takes place. A new headquarters is inaugurated in San Giuliano Milanese too and Anna Focarete Terenzi joins the Company.

CloseTRIPLASTIC, thermoplastic molding company, is born, in which TERENZI Srl participates. This makes new collaborations possible, such as the one with the Co. Modecor and moreover to strengthen those already underway, such as with the Co. Luceplan.

CloseTERENZI Srl acquires a new role as prime contractor, providing integration of metal and plastic products and services. The very first project in cooperation with the client is "Pulilux PL515" for Vorwerk Folletto.

CloseCo. TRIPLASTIC is purchased. Luigi Ubezio joins the Co., Luca Terenzi becomes CEO and takes over a significant share of the company. Of these years the important computerization of the orders for the KONE and the acquisition of complex design projects, such as "Aeros" for Louis Poulsen.

CloseDORVAL, plastics molding company with own products, is purchased.

CloseELEMENTI di LUCEPLAN, dealing with architectural lighting, is founded. The new multi-purpose Assembly Department is inaugurated.

ClosePLANIUM Srl was initially founded together with Design Group Italia and the Morettin family. The company designs and manufactures innovative, self-locking and raised flooring systems with textured metal finishes.

CloseThe Terenzi CAOSCREO brand was born: lighting and furnishing accessories created by young and successful designers, made of folded and painted metal.

CloseORIGAMI STEEL was born, Terenzi brand, which offers furnishing accessories and functional decorations in painted metal, in many color variations, for garden and home.

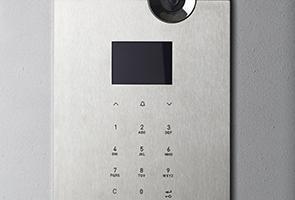

CloseTerenzi Srl, as evolved, is increasingly a center of various expertise, innovating services, equipment, machinery and specializing team synergy, to provide customer service, competitive products and quality. Davide Medri, Martinelli Luce, KOH-I-NOOR, Maurizio Galante, Cerruti Baleri, Driade, EmilCeramica Group and Comelit Group are some of the clients acquired in recent years.

CloseTerenzi Srl is the protagonist in the pavilion of Azerbaijan during Milan Expo 2015, with the Bright Flowers made for Simmetrico after a project of Studio Voltaire. In different colors, in two heights, the flowers contain a sophisticated technology. Running your hand over the Flowers, the light intensity changes. In addition, for the Azerbaijani pavilion Terenzi "illuminates" other two symbols of this distant land: the Pomegranate Tree and the majestic and robotic Eagle.

CloseTogether and for Digital Habits, Terenzi Srl challenges technology and modernity developing "Cromatica", multifunctional object, that contains light and music. On the body of the product a USB port is inserted, which recharges smartphones and audio players. Through a connection, you can program the color, the light intensity and the diffusion of music.

CloseAfter the successful cooperation for Expo, the partnership between Lighting of Studio Voltaire, Engineering of Digital Habits and Industrialization of Terenzi Srl giving rise to ILLUMINANCE, dedicated to the special custom made lighting products. Then, several Light projects were born including "Kupa", suspension lamp realized for the best Italian, French and Spanish Iper Carrefour stores.

CloseA flame gives off the light and a LED returns it, Francisco Gomez Paz in his project is inspired by the Scandinavian oil lanterns: Terenzi Srl for Astep ApS by Alessandro Sarfatti realizes "Candela", low power atmosphere lamp; it is eco-friendly, multifaceted object that illuminates wireless and recharges phones and via USB. The flame, produced by the combustion of bioethanol, gives off heat and feeds the LED light with just 2/3 watts.

CloseThis lamp was designed by Park Associati for Driade. Terenzi Srl has distinguished itself for the punctual work of engineering and the resolution of productive criticalities. "Lampsi" is made up of a central core wrapped in a rigorous graphic cage. Thanks to this shape, the light projects its diamond shape all around, creating geometric lines on the ceiling and walls.

CloseFor Astep ApS Terenzi Srl brings to light the works of a great name. Elegance and versatility run through time with a 1951 lamp designed in several versions by Vittoriano Viganò. All variants of the "VV Cinquanta" lamp are a reissue of the past and iconic design, industrialized with cutting-edge, contemporary production technologies. To these add the preseries of "Candela" by Francisco Gomez Paz, FLOS, "Mod. 2065" by Gino Sarfatti and "Nox" by Alfredo Haeberli, modern wonders.

CloseFor Condevo Spa, Terenzi Srl has reorganized an entire department designed to contain a 500ton press inside which an 8-station mold would be inserted, also designed and manufactured at Terenzi, for the serial production of a component for boilers: Flange. This latest product was added to a long-established list of technical components, made of various metals, for the multinational company.

CloseFor Kone Spa we produce the KSS 700 series, through transversal laser cutting, pin welding and bending technologies. The front part, visible, is made of AISI 441 Scotch Bright steel, elegant and satin-finished and is subject to our best Quality checks.

CloseFor Emerson Spa, Terenzi Srl produces the mechanical compass component. The detail is obtained starting from a customized tape in pre-galvanized iron (Fe Z6) by shearing. The shearing is carried out using a complex shearing iron, stepwise or progressive made by our tool shop, which involves a gradual deformation of the piece until the finished product is obtained.

CloseFor Ermete Giudici Spa, Terenzi Srl produces the metal and plastic components of the Onsen radiator. The cold-rolled metal parts are made using various technologies: laser cutting, shearing, bending and capacitor discharge welding.

CloseFor Kone Spa Terenzi Srl produces Dumbo, a new pushbutton panel for elevators. The panel is made by laser cutting, folding obtained with a bending machine and welding of the pins on the back. Each panel is customized as it has different configurations indicating the floors. The finishes are in brushed Steel and Carbon Black.

Closeof expertise and work

to deform 1.600.00 kg of metal sheets annually

at 250 mm/s to cut metal sheets up to 16 mm of thickness

to inject 80.500 kg of plastic materials every day

to meet your requests

of space to design solutions for metal and plastics

covered by two photovoltaic systems for a need of 75-80% of the required.

Our areas of expertise are 8, to make production processes more fluid and also offer integrated services.

The activity of co-design, engineering, mold design and automation is performed by the Technical Dpt. through 3-axis cad-cam software and applications, that are specific for the study and simulation of the productive processes. In order to grant the maximum flexibility, the project stations are able to import directly all the files, that have been generated by different cad application systems. The whole Technical Dpt. is managed and monitored by a software for the scheduling and the calculation of the order summary. The same system also allows customer access through a dedicated IP address, to verify the activity progress status.

The machine fleet includes high-speed machining centers for the processing of hardened materials and high-power machinery for large-sized processes (1,000x2,000x500 mm). There are also wire EDM (WEDM) and die-sinking EDM (EDM) with automatic electrode change. The grinders are equipped with numerical control to manage the grinding wheel sharpening cycle and the height recovery.

The tooling department includes the design and construction of progressive, transfer and recovery dies for shearing and drawing of sheet metal and molds for injection and/or overmolding with polymers; it is also equipped with 3-axis milling machines, including gantry ones, with a spindle speed of 15,000 rpm.

By means of high-tech laser cutting lines, CO2 and fiber, with a cutting power of 2,000 watts and a working range of 1,500x3,000 mm, prototypes, semples and pre-series can be realized in very short time and with low costs. In additions, thanks to the loading and unloading robots, it is possible to carry out large productions without having to prepare molds and consequently facilitating the reduction of the investments. To serve the line, an automatic warehouse has been installed, that is synchronized with the Company computer system. The loading double tower allows the storage of 150,000 Kg of raw material, divided according to type and size, in 45 loading platforms. A specific laser station is dedicated to the processes of precise marking, with which labels, inscriptions, Company logos, customizations, can be created.

The latest generation of the combined processing line is equipped with a sheet loading and unloading system.The working field is 1,250x3,000 mm and the turret operates 54 rotating tools: the machine, in addition to laser cutting and classic punching operation, can realize: ribs, folds, drawing, threading, bevels, etc. All the equipment necessary for the optimization of production cycles are studied by the internal Technical Office.

Two 130-tons down-stroking press brakes with a 3,000 mm max bending dimension represent one of the latest technological innovation. They have a three-dimensional numerical control for the automatic management of the bending cycle (automatic tool change too) and the verification of the interference; the line is equipped with compensation cylinders to correct any beam deflection and with a bending correction device to ensure consistent bending accuracy. These systems, combined with high technical characteristics, allow the execution of "air" bending with high acuracy; this reduces the number of tools necessary for the production. The set-up is very fast thanks to the fixing system with quick coupling and allows a large variability of production without impacting on manufacturing costs. For large series production, the machine is controlled by an anthropomorphic robot with a loading capacity of 5 kg.

The available machines include double column machanical presses with slowdown during shearing (Lever Drive) and even couterbalanced, with power range is from 45 up to 250 ton. Computers on board allow a quick and safe set-up of the tools; the production is monitored in real time with a computerized system that allows loads and discharges of stocks in the warehouse to check the order situation. The supply line can be pneumatic, mechanical or electronic (with variation of pass by Plc control); if necessary, a mechanical or an electronic transfer or a robot can be used for production. In addition we complete our machinery asset with hydraulic presses with capacities from 100 to 160 tons.

Electrical and hydraulic power presses from 40 tons to 350 tons are available. A tilting 45 tons press can be used for over-molded pieces with manual insertion. All the presses are equipped with a master batch unit and are fed by an automatic storage system which manages the dehumidification phase and the distribution of the raw materials. The 320-ton press is equipped with a Cartesian robot used for the extraction, processing and palletizing of pieces.

3 automatic and further 4 semiautomatic stations perform the following types of managed welding:

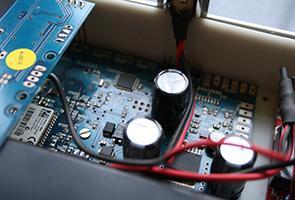

The assembly ad wiring departments was created with a concept of multifunctionality; in fact, different pallet areas have been provided for handling a large and varied stock of semi-finished products. Moreover, an aerial system was organized to supply high flexible workstations where several tools (manual, pneumatic and hidraulic) make available different purposes. A control testing device is used for checking and certifying electrical products (earth ground).

The company is equipped with automatic warehouses connected to the management system for storage and supply; a warehouse therefore installed to serve the lines, synchronized with the company IT system. The double loading tower allows the storage of 150,000 kg of raw material, divided by type and size, in 45 loading platforms.

Constant monitoring of all production processes in real time also takes place through the management system: each machine is connected to a terminal to which the data relating to production times are sent to the company management system.

"Ho scoperto un nuovo disco chiamato Greenyl che vanta un basso impatto ambientale e vorrei presentarvelo. [....] Poiché non utilizza cloruro di polivinile (PVC), è riciclabile al 100%, il processo di produzione utilizza energia rinnovabile ed è prodotto senza additivi tossici, il che lo rende un disco che riduce l'impatto sull'ambiente."

COMMERCIAL

commerciale@terenzisrl.it

TECHNICAL OFFICE

ufficio.tecnico@terenzisrl.it

ADMINISTRATION

amministrazione@terenzisrl.it

WEB DESIGN

Andrea Nobilio Comunicazione

MADE BY

PTEK - Software & Web

Privacy Policy